Hansoll Textile strives to grow together with global fashion companies by prioritizing customers and their satisfaction.

Business

Customer Satisfaction Comes First

Main Customers

Global Network

As of 2025, Hansoll Textile has 7 overseas subsidiaries with 13 wholly owned factories producing 32 million garments each month through

494 production lines.

|

7 Different Countries |

Established overseas subsidiaries in Vietnam, Indonesia, Cambodia, Guatemala and Nicaragua, in addition to Korean headquarters and US location | |

|

13 Owned Factories |

Operating 13 owned factories in South East Asia and Central America region | |

|

494 Total Lines |

A total of 494 lines operating in our factories | |

|

31,058,000 pcs/month |

Produce 32 million pieces of t-shirt equivalent monthly | |

Design & Digitalization

Phygital Product Development

We create, we support, we collaborate, we partner for your creative and valuable products through high digital technology in fashion.

We create, we support, we collaborate, we partner for your creative and valuable products through high digital technology in fashion.

Forecast & Analysis

|

Co-creation & Collaboration

|

|

Physical & Digital product development

|

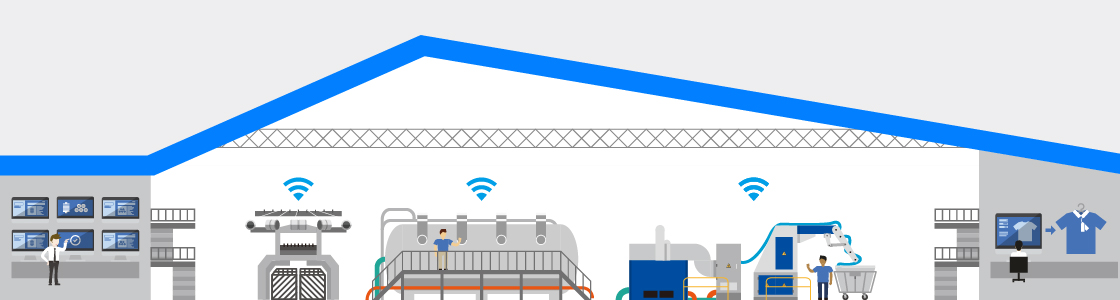

Smart Factory

Hansoll is building the first Smart Factory in the textile industry integrated with automated processes and facilities.

GD MES |

|

|

Fabric QR |

|

|

Sewing MES |

|

|

Janet System |

|

|

QMS |

|

|

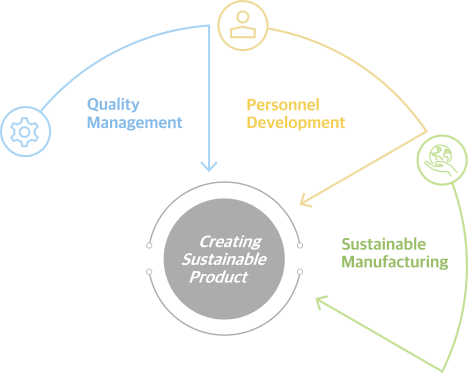

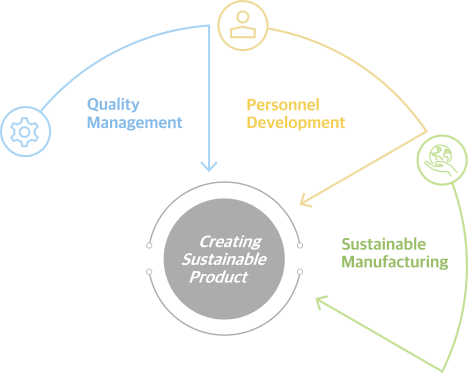

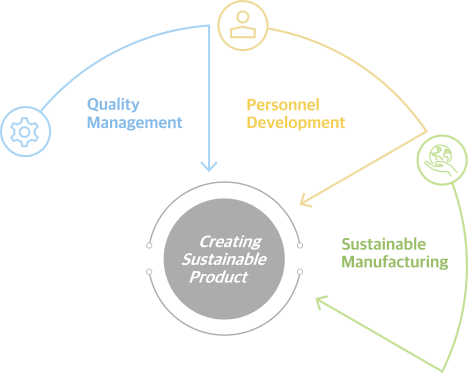

Quality Assurance

At Hansoll, we have continuously developed our own quality management system with ‘ESG’ in mind and it enables the implementation of a systematic approach to sustainable growth and fulfillment of customer’s requirements by making quality products at the right time.

Quality Management |

|

|

Personnel Development |

|

|

Sustainable Manufacturing |

|

|

Manufacturing Excellence

We Maximize value and ESG management through innovative systems and continuous improvement.

|

Digital Manufacturing

|

|

|

Continuous Improvement

|

|

|

Coexistence

|

|

Business

Customer Satisfaction Comes First

Main Customers

Hansoll Textile strives to grow together with global fashion companies by prioritizing customers and their satisfaction.

Global Network

As of 2025, Hansoll Textile has 7 overseas subsidiaries with 13 wholly owned factories producing 32 million garments each month through

494 production lines.

| 7 Different Countries | 13 Owned Factories | 494 Total Lines | 32,058,000 pcs/month |

| Established overseas subsidiaries in Vietnam, Indonesia, Cambodia, Guatemala and Nicaragua, in addition to Korean headquarters and US location | Operating 13 owned factories in South East Asia and Central America region | A total of 494 lines operating in our factories | Produce 32 million pieces of t-shirt equivalent monthly |

Design & Digitalization

Phygital Product Development

We create, we support, we collaborate, we partner for your creative and valuable products through high digital technology in fashion.

|

Forecast & Analysis · Global fashion trend forecasting · Market trend analysis · Fabric trend and development · Season color & graphic trend research & development |

|

|

|

Co-creation & Collaboration · Co-creating seasonal collections · Trading ideas and market information · Designing & Developing products together · Partnering as one team with brand’s creative team |

||

|

Physical & Digital product development · 3D digital fashion creation · 3D digital design collaboration · 3D digital technical design product development · Physical product development |

Smart Factory

Hansoll is building the first Smart Factory in the textile industry integrated with automated processes and facilities.

|

|

|

|

|

| GD MES | Fabric QR | Sewing MES | Janet System | QMS |

|

· Developed our own ERP system that links various data such as materials and production |

· Real-time visibility into logistics flows for instant status management |

· Efficient production management with real-time productivity/reject rate visibility |

· Improving Individual Performance Management and Individual Worker Behaviour |

· First-class quality and reproducibility with zero rejects |

| · Systematic material management and a barcode system to check production errors | · Identify fabric overages and shortages by comparing consumption | · Cost improvements due to reduced counting headcount | · Improved line balance management and Off Standard Time management | · Big data-based real-time production information management system |

Quality Assurance

At Hansoll, we have continuously developed our own quality management system with ‘ESG’ in mind and it enables the implementation of a systematic approach to sustainable growth and fulfillment of customer’s requirements by making quality products at the right time.

|

|

|

| Quality Management |

Personnel Development |

Sustainable Manufacturing |

|

· Systematic Process · Risk Management · Measurement / Analysis · QA Manual / SOP · Factory Quality Assessment · ERP System |

· Calibration · Empowerment · Workforce Evaluation · QA/QC Training · Certified Auditor · Sewer Training |

· Zero Defect · Real Time Data · Material Traceability · Traffic Light System · Sewing MES System · Recycled Material Process |

Manufacturing Excellence

We Maximize value and ESG management through innovative systems and continuous improvement.

|

|

|

| Digital Manufacturing | Continuous Improvement | Coexistence |

|

· Automation System · Real Time Information - WMS & MES · Cost Optmization - GSD & FastReact |

· Environment Optimization - 5S + Safety · Production Efficiency - Lean Engineering · Value Maximization & Continuous Improvement |

· Provide Training & Personal Development · Competitive Compensation System · Building Trust between Employees & Customers |